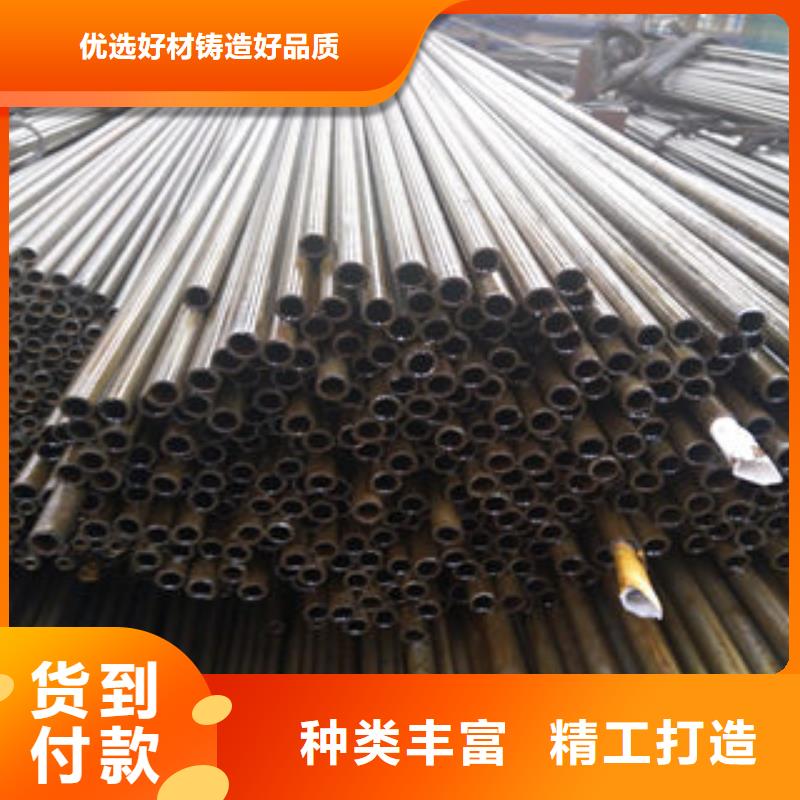

精密管下单即发货

更新时间:2025-10-26 19:12:20 ip归属地:梧州,天气:多云,温度:17-28 浏览:1次

- 发布企业

- 大鼎金属材料(梧州市岑溪市分公司)

- 报价

- 电议

- 品牌

- 电议

- 供货总量

- 电议

- 运费

- 电议

- 关键词

- 无缝钢管

- 所在地

- 高新区新东环路路西钢材市场58号

- 联系电话

- 0635-8888940

- 手机

- 15315719115

- 联系人

- 孙经理 请说明来自商助贸易宝,优惠更多

详细介绍

梧州岑溪大鼎金属材料有限公司成立十余年来,承蒙社会各界朋友和广大用户的关心、支持与厚爱, 无缝钢管业务得到了的长足发展。目前,公司 无缝钢管产品品种丰富,技术含量高,与我们合作,让您“信心、放心、舒心”。

山东大鼎钢管厂预计天津冷轧市场价格将稳定稳定。经过长时间的高开盘冲击操作,市场普遍处于警戒状态,虽然中间规格没有调整太多,但小厂资源比上周五可放宽10元/吨装运。

Bearing cold-drawn seamless steel tube has higher deformation resistance (see metal deformation resistance), is more sensitive to temperature, the lower the temperature, the higher the deformation resistance. When cold rolling seamless steel tubes are used for hot rolling bearings, the cold rolled山东大鼎金属材料有限公司 steel must be strictly protected. The production of bearing cold-drawn seamless steel tube is sometimes limited by sizing machine and straightener, force and straightening ability decline. The force increased significantly. The drawing force of cold drawn seamless steel pipe is about 50% higher than that of low carbon steel tube.

山东大鼎轴承冷拔无缝钢管的宽度比碳钢宽10%~20%,但在885~1195℃范围内温度变化很小,为控制冷拔无缝钢管生产中金属的横向变形提供了方便。冷拔无缝钢管的外径为6mm,壁厚为0.25mm,外径为5mm,壁厚小于0.25mm。其精度和表面质量明显优于热轧(膨胀)管。然而,由于技术的限制,其口径和长度受到一定的限制。一般长度为5-8米。我厂生产的冷拔钢管长度为18米,不受任何限制。缝合钢管。

山东大鼎钢管厂Seamless steel pipe is mainly produced by hot rolling, and extrusion method is mainly used to produce low plasticity high alloy steel pipe or special-shaped steel pipe and composite metal pipe which is difficult to pierce. Cold rolling and cold drawing process can make hot rolled tubes into small diameter thin-walled steel tubes. Welding steel pipe technology is simple, high production efficiency, low cost, and product variety is expanding day by day. Inventory or inventory increases capital risk. Tool Rust Removal: It is mainly used to grind steel surface with wire brush and other tools. It can remove loose or convex oxide scale, rust, welding slag and so on.山东大鼎金属材料有限公司

电动工具除锈可达到Sa级,如果钢表面粘附有固体氧化皮,不能满足建筑施工中保温和防腐施工线深度的要求。无缝钢管一般由优质碳素结合钢16Mn、5MnV、低合金结构钢40Cr、30CrMnSi、45Mn2、40MnB等合金钢经热轧或冷轧制成。低碳钢制成的无缝管主要用于流体输送管道。用45和40Cr等中碳钢制成的无缝管用于制造汽车和拖拉机等机械零件。一般来说,要保证无缝钢管的强度和扁平度。热轧钢管是在热轧或热处理中输送的,冷轧是在热处理中进行的。两个过程综述热轧(挤压无缝钢管):圆坯加热穿孔三辊横轧、连续轧制或挤压汽提定径(或减径)冷却坯管矫直水压试验(或探伤)标记储存。

Oil quenching causes surface deterioration easily. Due to the high surface activity, significant thin layer carburization can occur under the action of short and high temperature oil film. In addition, the adhesion of carbon black and oil on the surface is not conducive to simplifying the heat treatment process. The development of vacuum quenching technology mainly lies in the development of single gas cooled quenching furnace with excellent performance. Double chamber furnace can also be used for gas quenching (front chamber air jet cooling), but the operation of the two stations makes it difficult to load a large number of furnace, and easy to cause workpiece deformation or change the direction of workpiece quenching. NG deformation during high temperature movement.

山东大鼎钢管厂公式计算钢管的理论重量:W=(D-S)*S*0.02466,其中W=钢管每米的重量;S=钢管的公称壁厚;D=钢管的公称外径,光亮管的表面质量i清洁、无氧化层、无裂纹、折叠、轧制、结疤、分离层和条纹。